It is necessary to include a technical drawing to your order when your 3D CAD model includes:

1.Threads (internal or external)

2.Features with tolerances that exceed the standard.

3.Individual surfaces with specific finishing requirements (surface roughness etc)These requirements cannot be conveyed in a 3D CAD file.

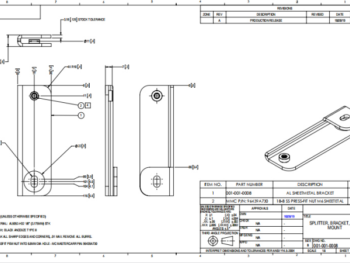

Even if your design does not include the above, it is generally a good practice to accompany your 3D CAD file with a drawing when placing a sheet metal part order. Usually, the 3D CAD file is used for programming the laser cutting machine and the drawing is used as a reference throughout the laser cutting process. Most sheet metal fabrication service providers can also manufacture parts directly from a technical drawing and they often prefer them over 3D CAD files, because:

- They are trained to interpret quickly the geometry of a part from the 2D drawing

- It is easier to identify the main dimensions, functions and the critical features of a part

- It is easier to assess the cost of manufacturing the part

There are many different standards and best practices for drafting a technical drawing. It does not matter which techniques you use to draft your technical drawing, as long as all the technical requirements are communicated clearly.